Trade

MDF sourced from renewable sources in North America. Polymer laminate surfaces that are recyclable and common among everyday living. Adhesive that creates a moisture barrier from daily living. The environmental benefits make Ultra Panels the best choice for modern eco-friendly interiors.

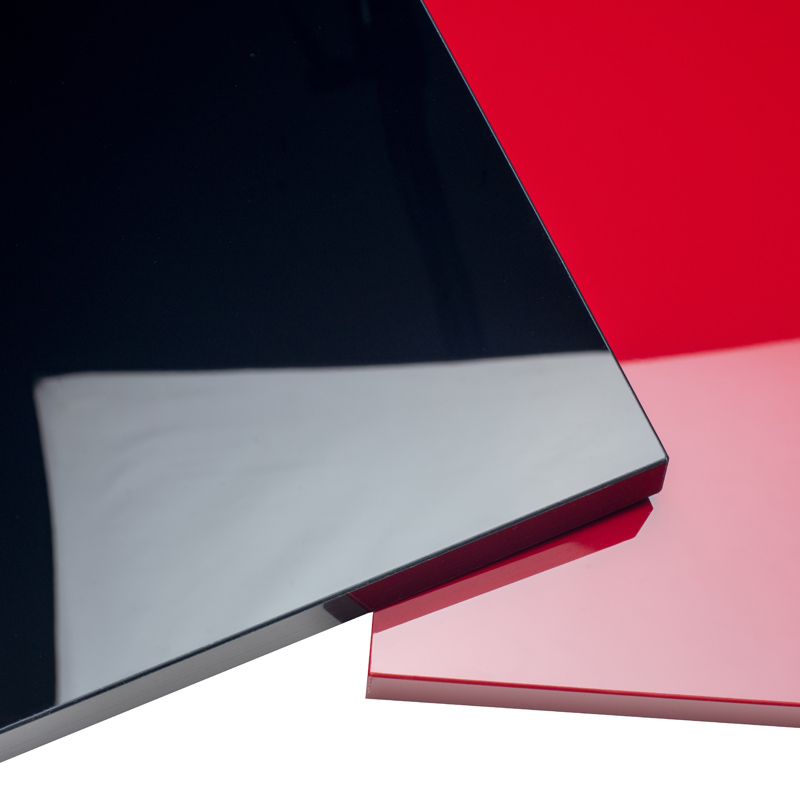

ULTRA-X Hard Coated Acrylic (ABS PMMA) is the solution for the ultra-luxury modern interior. This mirror-like, high gloss surface gives a radiant look and feel that is effortlessly sophisticated. Not only does it look good, it has the highest scratch and abrasion resistance in the acrylic high gloss furniture film category. The surface is suitable for food and easy to clean. Scratch resistant lacquered high gloss and super matte acrylic surface combined with a PUR adhesive bond layer make it water resistant like no other product in the furniture industry.

Our Ultra-X HCA (hard coated acrylic) should be your only choice for commercial fixtures in retail and hospitality environments. Our surface outperforms any other high-gloss acrylic in impact, abrasion and stain resistance. Feel free to request independently verified lab test results that show the quality is unsurpassed.

Ultrapan Ultra-X acrylic high gloss is elegance as its best.

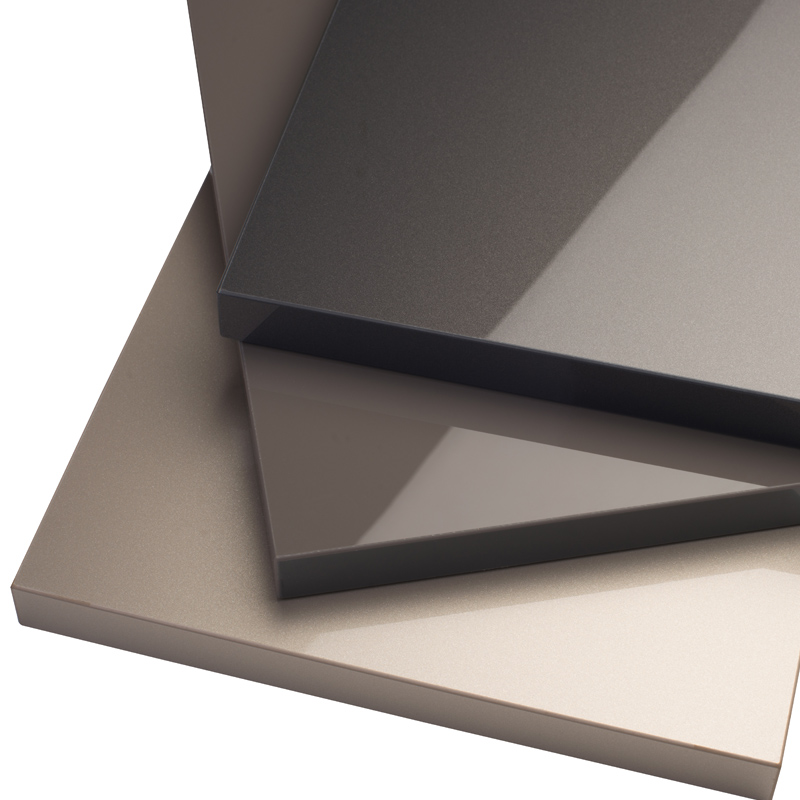

Ultrapan Ultra-X acrylic super matte is soft, comforting and composed.

Both ultra high gloss and super matte feature our hard coated lacquered, scratch resistant surface that sets us apart from the most common acrylic laminates.

Ultrapan Ultra Gloss HCP (hard coated poly ethylene terephthalate or PET) is the ideal surface solution for furniture, closets, multi-family or any ultra-modern interior. This is where contemporary and affordability meet. Performance is not compromised on this finish. Our hard coated PET (HCP) surface meets the scratch resistance, stain and chemical resistance of our HCA surfaces. Only Ultra-Gloss or Ultra-Matte HCP can be miter folded or post formed.

Chose Ultrapan HCP to meet a budget without sacrificing performance and style. Its value won’t be beat. Its modern look won’t be ignored.

Stand out with all the ULTRAPAN products. You won’t be part of the crowd when you use our gloss or matte polymer surfaces. We have given style a whole new look. One that will stand up to the busy, high-traffic environments that require ultra-modern finishes.

Ultra Bond

Ultra-Bond is not only the relationship our customers have with their ULTRAPAN furniture. It is also the cleanroom environment we apply specially formulated PUR moisture curing hot melt adhesive. PUR is known for its aggressive tack and very fast handling strength. Parts can be moved, trimmed, and even routed in minutes rather than hours. This powerful adhesive allows our polymer surfaces to be bonded to various substrates using a very thin layer of polyurethane reactive (PUR) glue to decrease orange peel and block moisture from the core.

Ultra-Bond gloss and matte production can be found all across North America. Our strategically located lamination lines can service case good manufacturers and furniture makers anywhere in the United States and Canada. Our production plants are listed below:

Ultra-Bond technology allows us to customize your substrate. Panel sizes from 4×8 to 4×10 and ¼” to 1” thickness panels allows us the greatest flexibility to meet your custom need. Typically, MDF is used however fire-rated, plywood, moisture resistant, polymer and other cores are also an option. Feel free to reach out for your next nationwide or worldwide project that requires custom production in the United States or Canada. We offer the greatest footprint for the most local gloss and matte panel manufacturing option in North America. In addition to having the best surface quality, our customers love the customization. With local manufacturing your options are limitless. Front and back can be as unique as the panel thickness and core type.

Ultra Edge

Our ultra gloss and ultra matte products already provide you the edge with outstanding surface stability, scratch and impact resistance, anti-fingerprint and easy to clean surfaces. This is cutting edge technology with high intensity color depth that is resistant to color change over time.

It wouldn’t be the same without edge banding to match. Our tapes vary from the exact same acrylic slit to size to end grain wood patterns for center panels in wall units, closets, media centers and other trendy environments.

Ultra-X acrylic tapes offer a guaranteed match like no other on the market. Our Edge material is the same material used for our surfaces. An Ultra-X Acrylic component will have the same surface top, bottom and every side. The acrylic tapes are produced in the same factory as the surface material. Therefore, wear, tear and lightfastness will all be equal. This finished part, over time will look uniform and equal all the way around over the life of the furniture. This is an exclusive offering unmatched by others. The Ultra-X tape match is guaranteed or it is free! Can anyone else say that?

Ultra Laminate

Ultra Panel. Laminate and Edge for a customizable solution

Ultra Laminates:

- Ultra-X acrylic laminates are available in quick ship 4×8 sizes (other sizes available by special order).

- Ultra Gloss laminates available in 4×8 or 4×10

- Ultra Matte laminates available in 4×8 or 4×10

- Ultra Wood laminates are 4×10 only

Ultra Panels:

- Ultra laminates applied to an MDF substrate or other substrates by special order including plywood core, fire rated cores and polymer cores. Finished sizes from ¼ inch to 1” inch.

- Panel substrates available from 4×8 to 4×10

Ultra Edge:

- Ultra X tapes are produced from the same acrylic used on the surfaces.

- Large Collection of Edges to match all of the Ultra Gloss, Matte and Wood in ¾” width with other sizes available by special order.

- Can be applied using standard, AdvantEdge laser or hot-air technology with a functional layer.